Key Takeaways

- Heavy-duty casters are essential for the efficient and safe movement of heavy equipment in industrial settings.

- Advancements in caster technology, such as ergonomic designs and innovative features, are improving workplace safety and productivity.

- Proper selection and maintenance of casters can lead to long-term cost savings and enhanced operational efficiency.

Introduction

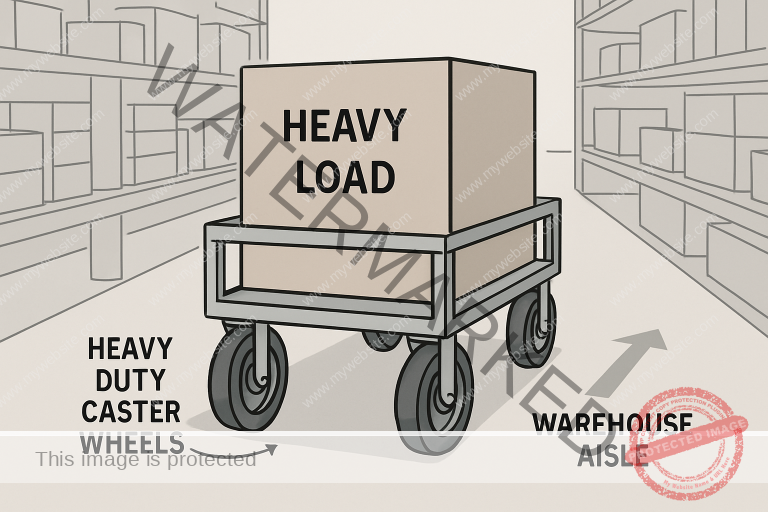

Industries worldwide rely on fast, safe, and reliable equipment mobility to ensure smooth operations. One game-changing innovation leading the charge is the use of heavy duty caster wheels. These specialized wheels provide vital support, allowing operators to move heavy machinery and materials with minimal effort, reducing downtime and risk of injury. Their robust construction is particularly effective in manufacturing facilities, warehouses, automotive plants, and even healthcare settings where handling substantial weights is routine.

Among the primary advantages of adopting heavy-duty caster wheels is an immediate boost in safety and efficiency. Built to withstand the rigors of demanding industrial environments, their engineering excellence ensures that even the heaviest loads can be transported smoothly, ultimately allowing businesses to streamline logistics and lower operational costs. When integrated with modern carts and racks, caster wheels enable workers to maneuver bulky equipment in narrow aisles or over uneven surfaces with greater confidence and ease.

Advancements in Caster Technology

The evolution of caster design has brought about significant improvements in both capability and performance. Recent technological advancements, such as sophisticated braking systems, ensure that equipment remains securely in place, minimizing the risk of accidents during loading or unloading. This added control is particularly valuable in high-traffic environments where safety is paramount. Modern racks and trolleys employ ergonomic caster fittings that reduce worker fatigue, allowing for better productivity and fewer workplace injuries.

Beyond visible mechanical improvements, casters often feature intuitive enhancements like directional locks and anti-vibration mounts. These innovations lower the manual effort required and prevent load shifting, laying the groundwork for higher throughput and enhanced workplace morale.

Material Innovations Enhancing Durability

Advancements in material sciences have transformed the durability of industrial casters. Manufacturers increasingly utilize high-tech composites and specialty alloys—such as polyurethane blends and heat-treated aluminum—that offer superior resistance to abrasion, corrosion, and chemical exposure. These improvements maximize the caster’s load-bearing capacity and extend their operational lifespan, leading to substantial cost savings over time. For example, polyurethane treads often outperform rubber counterparts due to their ability to distribute weight evenly while maintaining flexibility and resilience.

Resourceful companies are investing in durable casters, not just for their immediate benefits but also for their long-term contributions to reduced maintenance bills and decreased production downtime. Industry experts note that choosing quality components like advanced casters significantly supports lean manufacturing initiatives and continuous improvement goals.

Ergonomic Design Enhancements

Ergonomics is a top priority in modern industrial equipment design, and heavy-duty casters are no exception. Precision ball bearings, smoother swivel mechanisms, and vibration-damping technologies help lighten workers’ load. As a result, operators expend less physical effort moving heavy carts or racks, leading to a safer environment with fewer repetitive strain injuries. Enhanced grip surfaces and foot-activated brakes provide additional control, empowering staff to stop or steer loads precisely as needed.

Worker Safety and Productivity

Adopting ergonomic caster solutions is key to improving workforce morale and demonstrating a commitment to employee well-being. The ability to handle heavy items safely lowers the odds of workplace incidents and boosts productivity by minimizing downtime due to worker injuries or equipment malfunctions. Research from the Occupational Safety and Health Administration (OSHA) consistently highlights the benefits of ergonomic interventions in reducing work-related musculoskeletal disorders.

Improved Load Distribution

Stable load handling is paramount in industrial environments where accidents can have considerable consequences. Today’s heavy-duty casters are engineered to optimize load distribution, prevent uneven wear, and maximize the stability of the load during movement. Innovations such as multi-layer treads and upgraded core materials deliver rugged support while reducing point stress on the floor and caster assembly. Enhanced ball-bearing assemblies within caster wheels further support smoother, quieter operation, even with the heaviest equipment.

Applications Across Industries

The adoption of heavy-duty casters extends across a dizzying array of sectors. In automotive plants, these casters allow vehicles and parts to be transported efficiently through assembly lines. Aerospace manufacturers rely on casters to maneuver massive components with precision. Warehouses use them to streamline pallet and rack movement, significantly improving supply chain speed. Heavy-duty casters are critical in supporting hospital beds, medical equipment, and patient transport in healthcare environments for greater mobility and safety. Their versatility makes them a staple component in any field that demands robust load handling and responsive movement.

Benefits of Heavy-Duty Casters

- Durability:Built for longevity, these casters minimize replacement needs and contribute to a lower total cost of ownership.

- Load Capacity:Engineered for hefty loads, ensuring safe and reliable material and equipment movement.

- Maneuverability:Designed to pivot and navigate tight corners swiftly, supporting agile operations even in space-constrained facilities.

- Ergonomics:Easier to operate, helping reduce workplace injuries and improve employee satisfaction.

- Safety:Equipped with advanced features like brakes and directional locks to keep loads secure and personnel protected.

- Stability:Ensures equipment remains steady during transit, lowering the chance of accidental damage.

Conclusion

Heavy-duty casters remain indispensable across modern industrial operations, from boosting safety and operational efficiency to supporting ergonomic best practices. Their adaptability and rugged construction give companies a competitive edge while protecting their most valuable assets: people and equipment. By embracing technological advancements and carefully selecting the right caster solutions for specific tasks, businesses can achieve higher levels of productivity and safety in every stage of their operation.